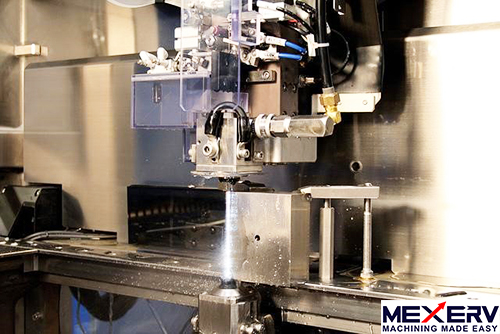

Wire/EDM Cutting

In Wire EDM machining (Electrical Discharge Machining), a thin strand of metal wire, with de-ionised water is made to cut through the metal with the help of heat from electrical sparks and ensuring the prevention of rust. Wire EDM Machining is an electro-thermal process. De-ionised water is used to conduct electricity.

The wire cutting operation is best suited for delicate or small work pieces that might get damaged during conventional machining or other traditional techniques. Apart from that, some common work pieces processed using wire cutting operation are:

- Thick parts which require a good finish or accuracy

- Complex shapes or narrow slots

- Larger parts which require accurate tolerances

- Delicate, hard, exotic/expensive or weak materials that

Advantages of Wire EDM

- Some simple or complex patterns that would be tedious to produce with conventional cutting tools can be produced with wire cutting.

- The dimensional accuracy is very high for close fitting parts.

- Minimal burr produced during the process.

- No need for custom tooling.